Fly Ash – A Sustainable Solution

for Stronger Concrete

Product Overview

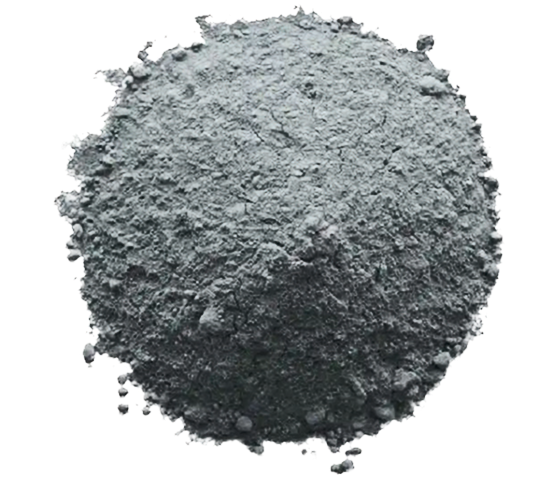

Fly Ash

Product Type:

Supplementary Cementitious Material (SCM)

Description:

It consists of spherical glassy particles that are rich in silica (SiO2), alumina (Al2O3), and iron oxide (Fe2O3).

Fly ash is a fine, powdery material produced as a byproduct from the combustion of pulverized coal in power plants.

Flyrash is an eco-friendly material for various construction and industrial uses.

Source:

India and Malysia

Unlocking the Full Potential of Fly Ash

Key Features

Enhance Strength, Durability, and Sustainability with every mix

Sustainable

Fly ash is a sustainable material that reduces the carbon footprint of concrete and other construction materials.

Chemical Resistance

It enhances the resistance of concrete to sulfate and chloride attacks.

High Pozzolanic Activity

It enhances the properties of concrete and provides long-term strength and durability.

Reduced Heat of Hydration

Fly ash helps in reducing the heat generated during the cement hydration process.

Cost-Effective

Fly ash is cost-effective and readily available, making it an economical choice for various applications.

Improve Workability

Lowers water demand, enhances slump, and extends workability for easier concrete mixing.

Versatile Applications

From concrete to roadways, Fly Ash is

shaping the future of infrastructure.

Concrete Production

Fly ash is widely used as a supplementary cementitious material in concrete production, reducing the need for Portland cement and lowering the environmental impact.

Brick and Block Manufacturing

It is utilized as an ingredient in the production of bricks and blocks, enhancing their strength and durability.

Mortar and Grout

It improves the workability and long-term performance of mortar and grout in construction projects.

Soil Stabilization

Fly ash can be mixed with soils to improve their engineering properties, making it valuable in construction and infrastructure projects.

Highway Construction

Fly ash is used in road construction for stabilizing soils and as a partial replacement for cement in concrete pavements.

Waste Stabilization

It can be used to stabilize hazardous and nonhazardous waste materials.

Technical Specifications

Engineered for Performance & Sustainability, Precise composition and properties to meet industry standards.

| Properties | Unit | ASTM C618 Class F |

|---|---|---|

| Silicon Dioxide, Aluminum Oxide, Iron Oxide (Si02 + Al203 + Fe2O3) | % | 70 Min |

| Sulfur Trioxide (SO3) | % | 5.0 Max |

| Moisture Content (H2O) | % | 3.0 Max |

| Loss on Ignition (L0I) | % | 6.0 Max |

| Fineness - Retained on 45 pm (No. 325) sieve | % | 34 Max. |

| 7 day (% of control) | % | 75 Min |

| 28 day (% of control) | % | 75 Min |

| Water Requirement (% of control) | % | 105 Max |

| Autoclave Expansion or Contraction | % | 0.8 Max. |

How we Handle Fly Ash

Ensuring Excellence: Quality, Storage, and Sustainability

Quality Standards:

Fly ash products conform to ASTM C618 and

other international standards for

supplementary cementitious materials.

Storage and Handling:

Store fly ash in a dry environment to prevent moisture absorption. Handle with care to minimize dust generation.

Environmental Benefits:

Using fly ash in construction materials significantly reduces greenhouse gas emissions and conserves natural resources. It is an environmentally responsible choice for sustainable construction practices.